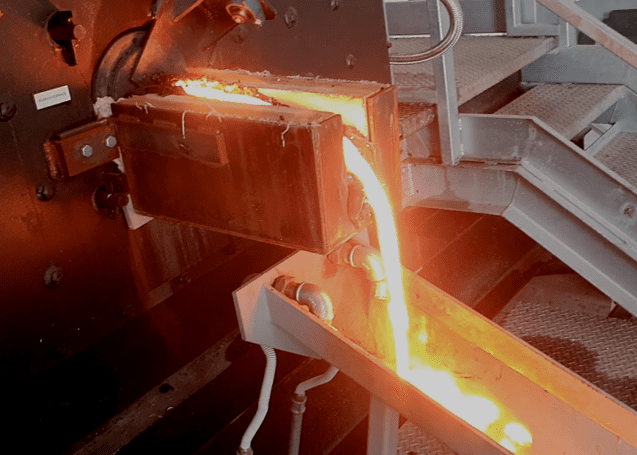

// SBM furnace for Stone wool //

Energy consumption: 1,6-1,7 MWh/t

// SBM for Stone Wool //

Flow rate: 3 t/h

// SBM for Stone Wool //

Melt temperature: 1550 C