// SBM //

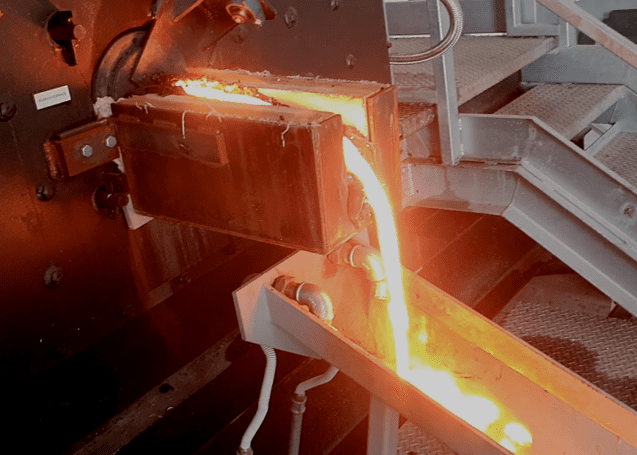

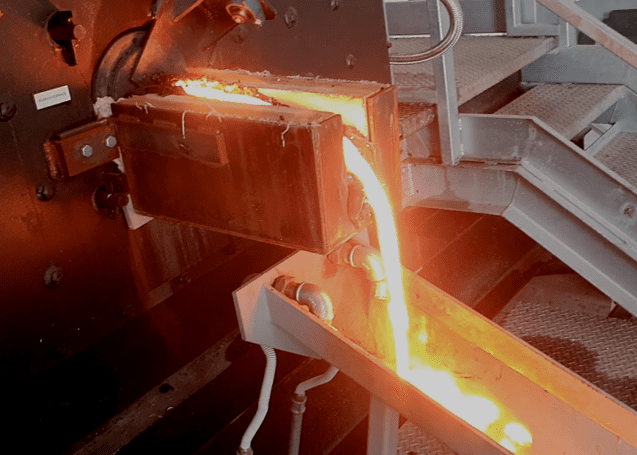

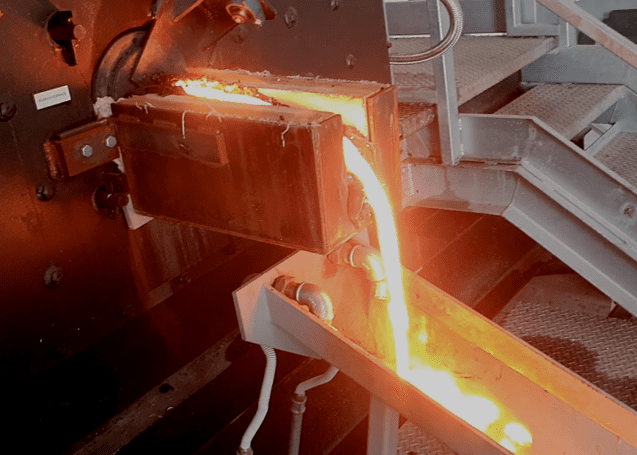

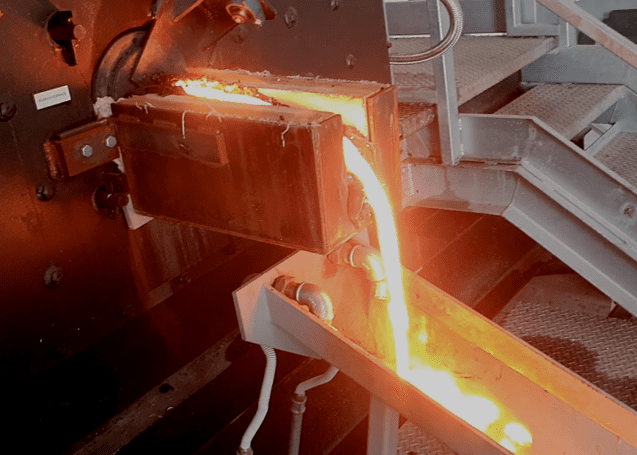

Burners are installed on the bottom of the furnace

// SBM //

The melting tank is made of water-cooled metallic panels - NO REFRACTORIES

// SBM //

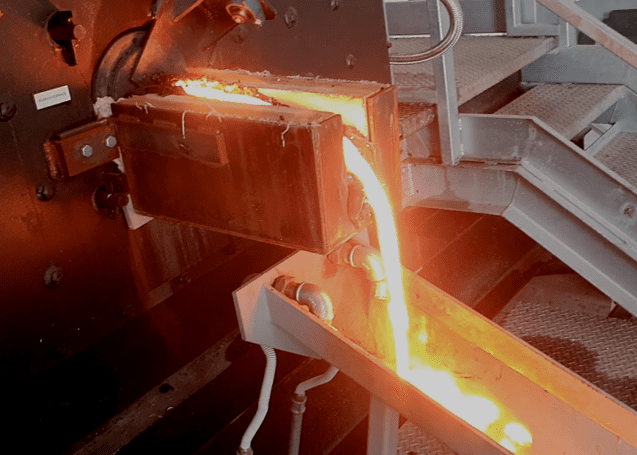

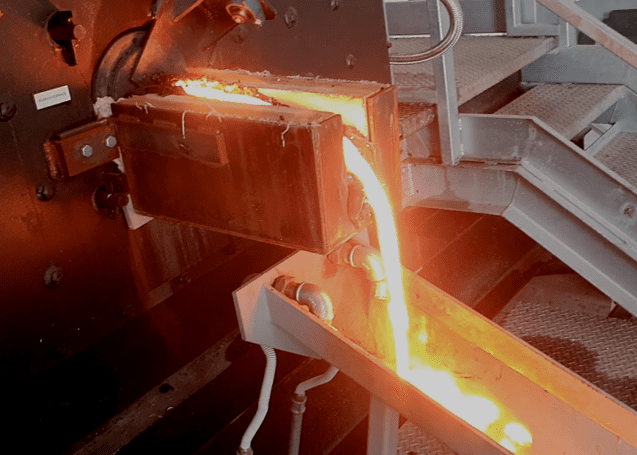

The batch is charged below the melt level

// SBM //

Volumic Melting

// SBM //

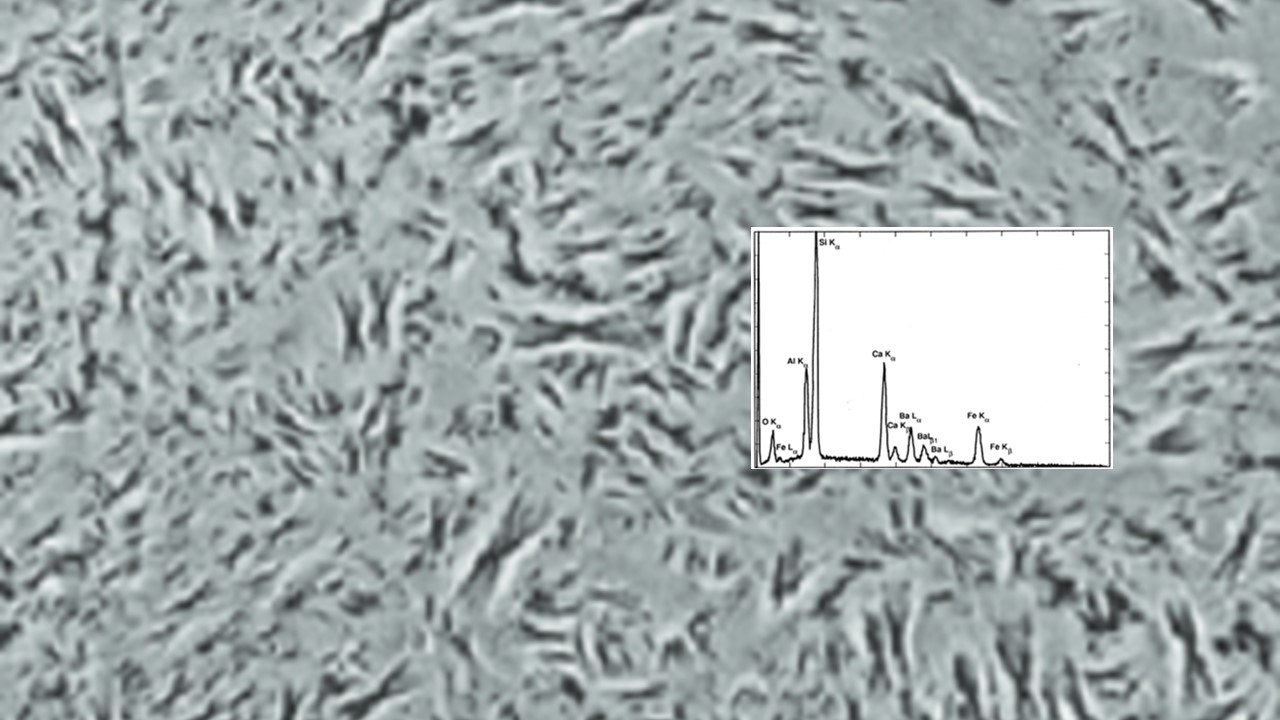

Chemical homogeneity

// SBM //

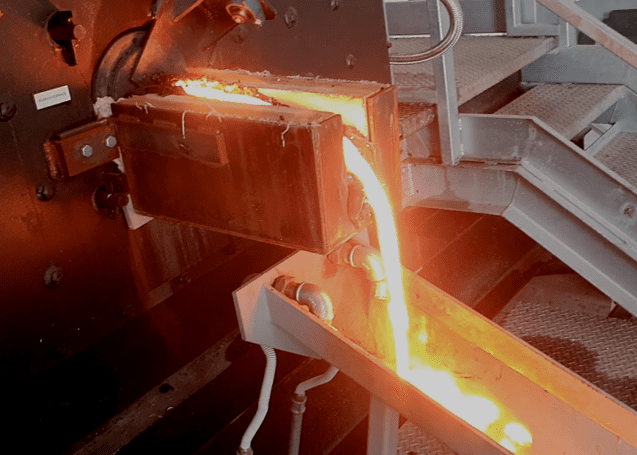

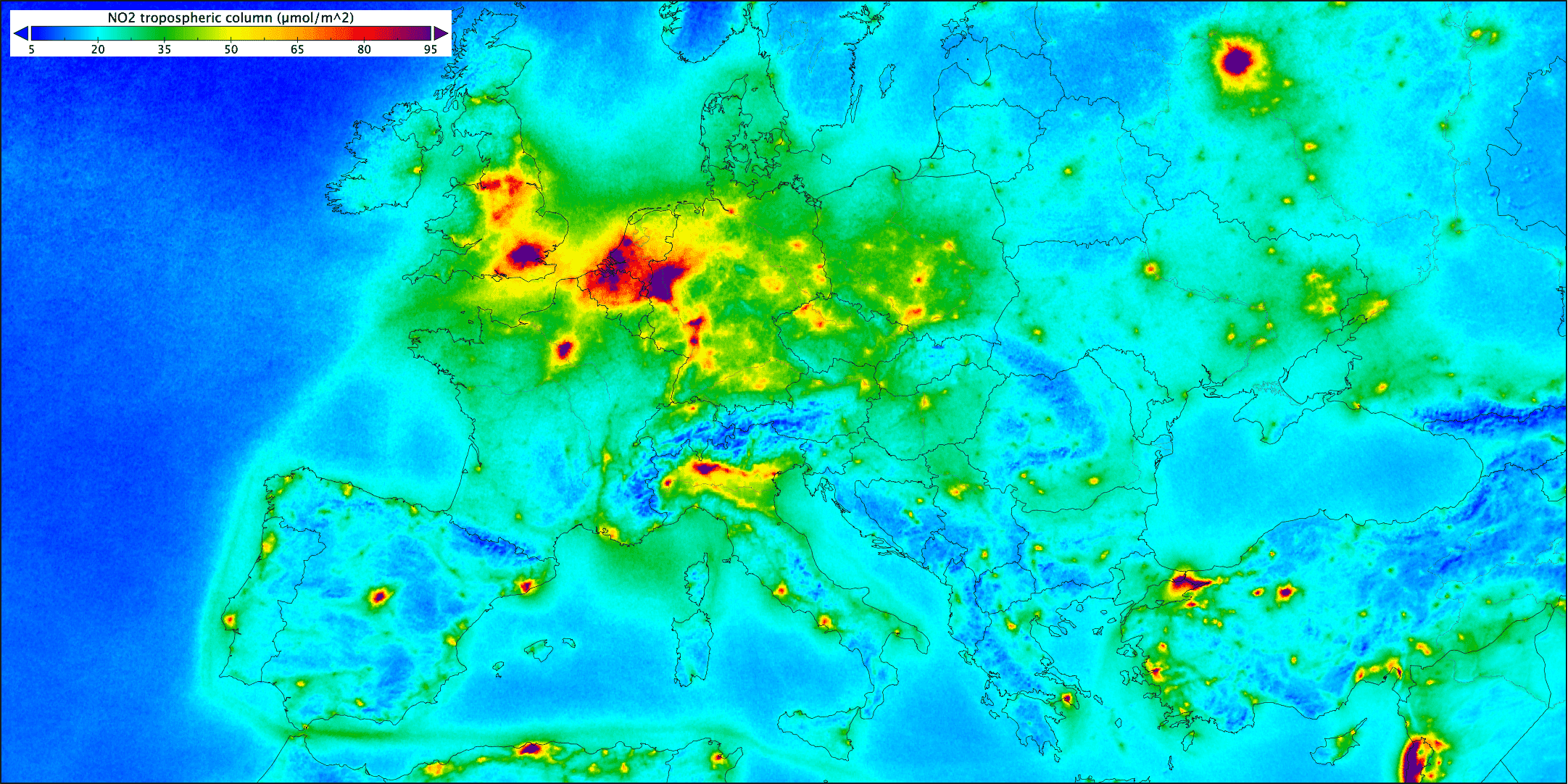

Low emission of NOx

// SBM //

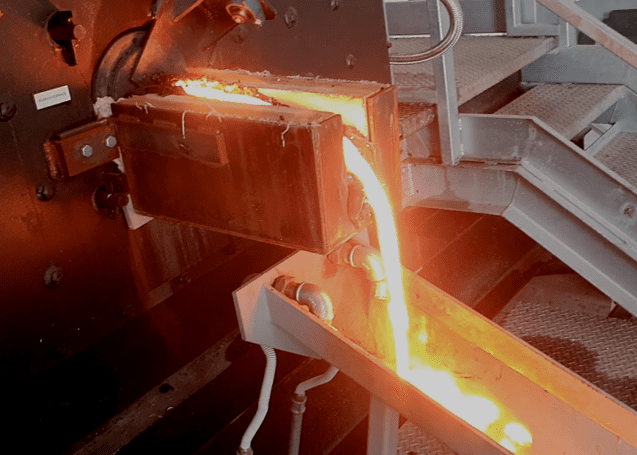

80 ton/day: Very compact size

// SBM //

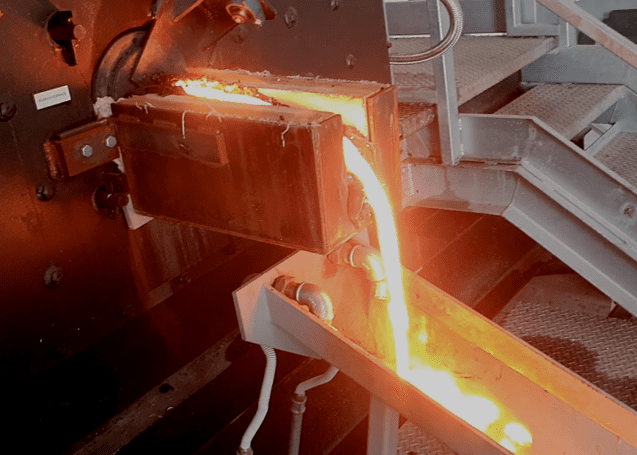

Able to work in "On - Off" mode - Reduction of opex!

// SBM //

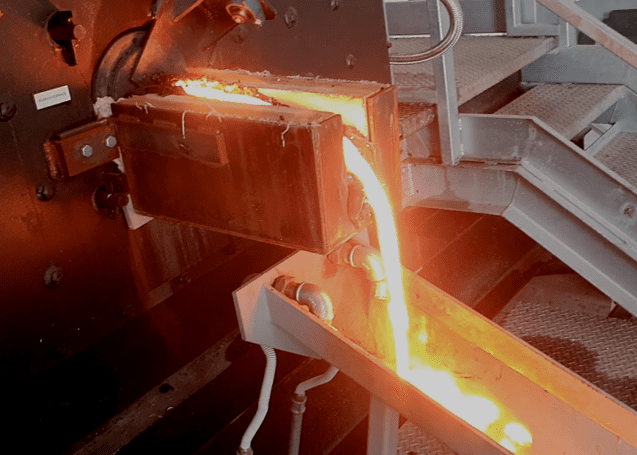

Estimated Payback Period 4 years!

// SBM //

Long service life